Traction Motor

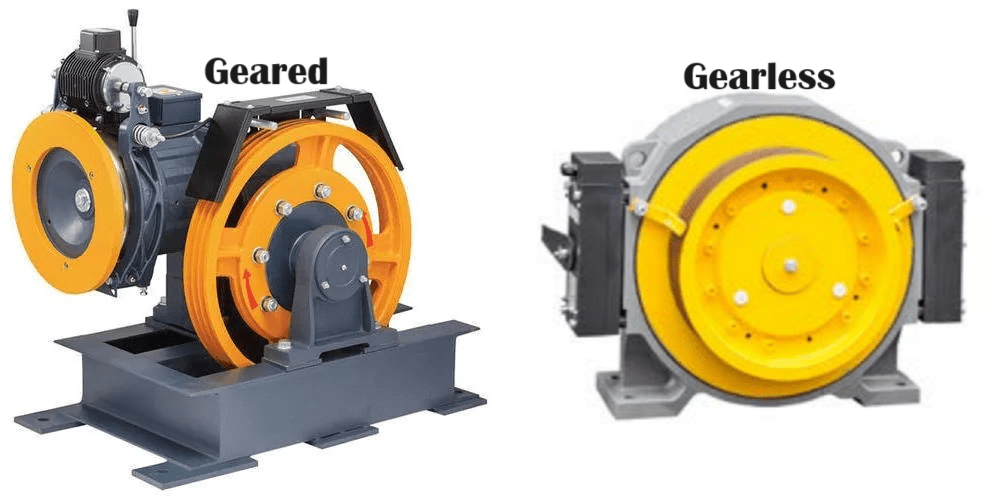

The traction elevator motor, a marvel of mechanical ingenuity, orchestrates the vertical ballet of modern buildings. Unlike its hydraulic counterpart, this motor employs a sophisticated system of counterweights and ropes, ingeniously leveraging gravitational forces to elevate and descend cabins with precision. Its intricate design ensures not only efficiency but also a smooth, uninterrupted ascension, akin to the glide of a hawk on thermal currents. The traction elevator motor, with its labyrinthine network of gears and pulleys, exemplifies engineering finesse, delivering a seamless symphony of motion that defies the mundane clatter of ordinary machinery. Traction machines are divided into two types: gear-equipped and gearless. Both are described below:

1. Traction Drive-Geared Machine

A gearbox is fastened to the AC or DC motor of a geared traction machine. The engine and gearbox are coupled, and the gearbox turns a wheel to help the rope move. They are also energy-efficient due to this technique.

The best use for this kind of elevator is a mid-sized building up to 300 feet. Furthermore, there’s a chance it could accelerate to 500 feet per minute. This, while not optimally the fastest, is nevertheless quicker than some elevators.

2. Gearless Traction Machine

The drive sheave of a gearless traction machine rotates instantaneously since the wheel is directly connected to the electric motor. The elevator cab moves forward and downward due to this rotation of the driving sheave. You can quickly determine whether a machine is gearless or geared by looking at whether all of its parts move consistently in the same direction.

The gearless machine can lift more weight and has an AC motor. This kind of equipment is perfect for use in high-rise structures because of its unique capabilities.

Differences Between Geared and Gearless Traction Elevators

Traction elevators operate on a pulley system. Ropes or belts attach the cab to a wheel on the motor. As the motor turns the wheel, the cab moves up and down. This system includes a counterweight, balancing the load and improving energy efficiency. To determine the best option, we can compare geared and gearless elevators across several categories.

- Design: In hotels and businesses in particular, the elevator’s appearance and functionality should blend seamlessly with the architecture of the structure. Because they are lighter and quieter, gearless elevators provide smoother landings and levels, as well as less vibration in the cabin and more seamless stop-and-start operations. These characteristics offer a more comfortable ride and a contemporary look that is frequently seen as upscale. Gearless elevators are the best option if you want a sleek, modern appearance. On the other hand, geared elevators can offer a nostalgic, vintage look.

- Height Revolution: Because traction elevators use a pulley mechanism, friction must be taken into account. Gear-driven elevators can effectively service buildings up to 20 stories high; but, as you go higher, the weight of the gearbox becomes a problem. A gearless direct-drive system is lighter in high-rise buildings, which lowers friction and energy loss and permits quicker speeds. As a result, building height influences the decision between geared and gearless systems. In order to make an informed choice, research is necessary.

- Speed: These elevator kinds differ greatly in their structural makeup, which has a major effect on their speed. Geared traction elevators are effective up to 75 meters and have a maximum speed of 152 meters per minute. Gearless traction elevators are capable of reaching 600 meters in height and 610 meters per minute. In terms of passenger weight, they can both carry the same amount of weight. For taller structures, gearless traction elevators are preferred due to factors like speed and height.

- Reasons to Have a Machine Room: The machine room is a crucial distinction between geared and gearless elevators. A machine room is necessary for geared systems since the wheel and motor are positioned above the shaft. Machine-Room-Less (MRL) elevators are named thus because gearless elevators, on the other hand, attach the wheel directly to the motor, doing away with the necessity for a machine room. To avoid overheating, machine rooms need proper lighting, climate control, and air conditioning. One disadvantage of geared elevators is that architects have to account for their large size.

- Energy Consumption: Modern design places a high premium on energy efficiency. Because they don’t have any geared type machines, using gearless elevator motors is smaller and consumes less electricity. Because of their smaller size and decreased friction, they use less energy overall, which improves performance. As a result, gearless motors are a more appealing and sustainable option.

- Maintenance: Keeping elevators in good working order requires regular maintenance. Because of their larger engines and gear components, geared elevators require more frequent lubrication and maintenance. On the other hand, gearless elevators are less expensive and easier to maintain, because they require no oil and have fewer parts.

- Pricing: Because they use smaller, less expensive motors, ropes, and belts, geared traction elevators are initially less expensive to build. But having a gearbox adds to the complexity and expense of maintenance, which includes frequent oiling to reduce wear and friction. On the other hand, even though gearless elevators could cost more up front, they might save money over time due to their lower maintenance needs.

Conclusion

Choosing between geared and gearless traction elevators involves considering building height, design preferences, energy efficiency, and maintenance requirements. Gearless elevators, with their advantages in speed, energy consumption, and maintenance, are often the better choice for taller buildings and modern designs. However, geared elevators can be suitable for lower-rise buildings and those seeking a historical aesthetic.

To get a modernized or replacement solution, you can contact MCE, Nidec Elevator Group

Good Article & Clearly Stated