Choosing the right elevator for your building involves more than just deciding to go up or down. When comparing traction and hydraulic elevators, several factors come into play, such as space limitations, budget, and usage needs, all working together to guide the decision.

Traction vs Hydraulic Elevators

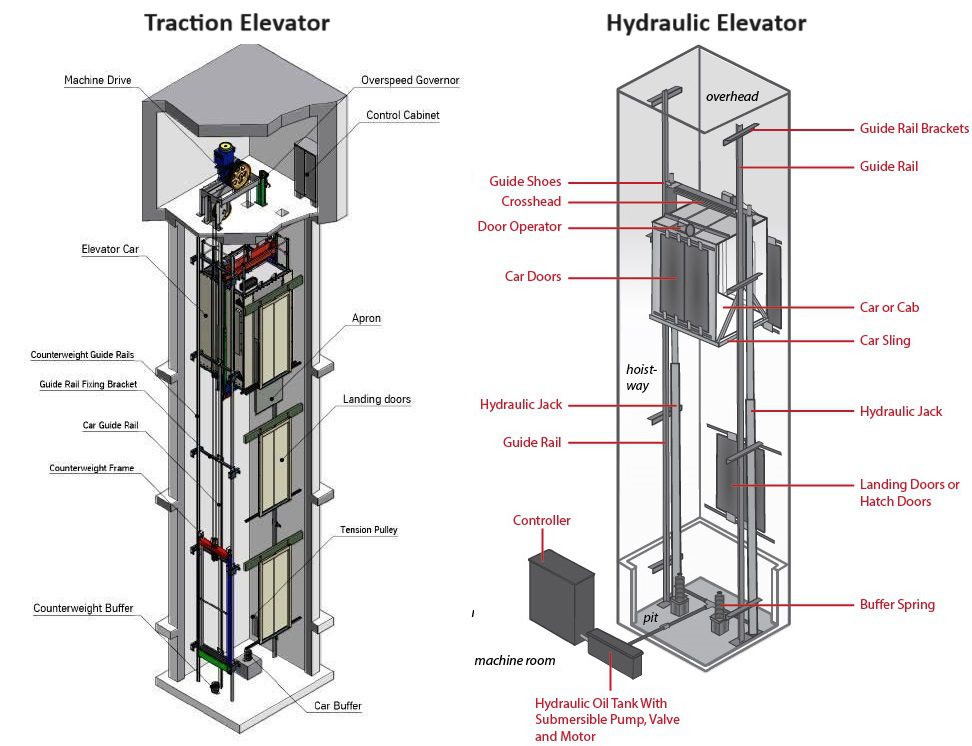

Traction vs Hydraulic Elevatos: Both hydraulic and traction elevators fulfill the essential role of conveying passengers and freight but operate through fundamentally disparate mechanisms. A hydraulic elevator leverages an electronic pump to channel oil into a cylinder, augmenting pressure to propel a piston, thereby causing the elevator to ascend. Conversely, a traction elevator employs a system of cables, pulleys, and counterweights to elevate the cab.

Efficiency: Hydraulic elevators, in comparison to their traction counterparts, necessitate greater power for operation due to the requisite pressure generation via the hydraulic pump. This often culminates in escalated energy consumption and higher operational costs over time.

Noise Concerns: Because of the audible emissions from the hydraulic pump and motor, hydraulic elevators usually operate with higher noise. In contrast, traction elevators, utilizing a motor-driven pulley system, generally function with reduced noise levels, providing a quieter user experience. Know how to solve it now.

Typical Uses: Although hydraulic elevators may offer a less seamless ride, they excel at bearing heavier loads in contrast to traction elevators and typically operate at slower speeds. Consequently, hydraulic elevators are predominantly favored in edifices with five stories or fewer, whereas traction elevators are preferred for mid- to high-rise structures where speed is of the essence.

Ideal for Tall Buildings: Hydraulic elevators are less suited for tall buildings as their efficiency diminishes with increased height, rendering them optimal for structures up to seven stories. Conversely, traction elevators are ideally suited for high-rise buildings.

Speed Constraints: Hydraulic elevators are typically subject to speed limitations, often capped at around 150 feet per minute (fpm), which may be inadequate for tall or bustling buildings.

Call Back Issues: Traction elevators statistically have a lower call-back rate compared to hydraulic elevators and require less maintenance. Nevertheless, hydraulic technology has been proven over the past five decades, while traction elevators also boast a commendable lifespan.

Cost Analysis: The financial disparities between hydraulic and traction elevators are intricate. While traction elevators generally entail higher installation costs, they exhibit superior energy efficiency once operational, leveraging counterweights rather than electric pumps for cab elevation. In contrast, hydraulic elevators usually involve lower initial costs and are often more economical to maintain over time.

Shaft Size: Hydraulic elevators demand less spatial allocation compared to traction elevators. In scenarios where adequate excavation for a standard pit required by traction systems is unfeasible, hydraulic elevators present a viable alternative due to their reduced pit requirements. Spatial availability can be a critical factor in elevator selection. Many hydraulic elevators can be configured with the machine room positioned atop the shaft, conserving space and aiding in maintaining optimal oil temperature for smooth operation. Conversely, traction elevators, including newer machine-room-less models, require considerably more space.

Lifespan: Traction elevators boast a longer service life and experience less component wear in comparison to hydraulic elevators, resulting in heightened durability and reliability over time.

Summary: Hydraulic elevators have limitations for high-altitude travel. They are unsuitable for buildings exceeding seven stories. Ultimately, opting for a hydraulic elevator is prudent if minimizing initial expenditure and pit area is paramount for personal usage in smaller buildings. However, traction elevators are preferable for lower noise, user-friendliness, smooth operation, enhanced passenger comfort, and extended longevity.

Frequently Asked Questions

Q: What are the primary differences between hydraulic and traction elevators?

A: Hydraulic elevators use an electronic pump to push oil into a cylinder, increasing pressure to move a piston that elevates the cab. Traction elevators use a system of cables, pulleys, and counterweights to lift the cab.

Q: Which type of elevator is more energy-efficient?

A: Traction elevators are generally more energy-efficient than hydraulic elevators. They use counterweights to assist in lifting the cab, reducing overall energy consumption.

Q: Are hydraulic elevators noisier than traction elevators?

A: Yes, hydraulic elevators tend to produce more noise due to the operation of the hydraulic pump and motor, whereas traction elevators operate more quietly with their motor-driven pulley system.

Q: In which types of buildings are hydraulic elevators most commonly used?

A: Hydraulic elevators are commonly used in buildings with five stories or fewer due to their efficiency in carrying heavier loads at slower speeds. They are less suitable for taller buildings.

Q: What are the speed limitations of hydraulic elevators?

A: Hydraulic elevators typically have speed limitations, often capped at around 150 feet per minute (fpm), which can be insufficient for taller or busier buildings.

Q: Which type of elevator requires more maintenance?

A: Hydraulic elevators generally require more maintenance than traction elevators, which have a lower call-back rate and longer service life. To know more about hydraulic maintenance, read Elevator Machine Room Oil Log: Hydraulic Edition.

Q: How do the initial costs of hydraulic and traction elevators compare?

A: Hydraulic elevators typically have lower initial costs compared to traction elevators, which have higher installation costs but offer superior energy efficiency over time.

Q: What are the space requirements for hydraulic versus traction elevators?

A: Hydraulic elevators require less space than traction elevators. They are ideal for scenarios where adequate excavation for a standard pit is not feasible, as they have reduced pit requirements.

Q: Which type of elevator has a longer lifespan?

A: Traction elevators generally have a longer service life and experience less component wear compared to hydraulic elevators, making them more durable and reliable over time.

Read another article about Choosing Right Elevator For Your Building.

Pingback: Choosing Elevators for Buildings: Key Technical Issues Explained